Introduction:

Belt weigher is an automatic weigher that continuously weighs bulk materials on the conveyor belt without subdividing the mass or

interrupting the movement of the conveyor belt.

ics-14 high precision electronic belt weigher adopts full suspension weighing bridge. This kind of bridge has no fulcrum and movable parts.

The long-term stability and high precision of this kind of electronic belt weigher are incomparable with other electronic belt weighers. Digital

signal transmission and processing technology, dynamic cumulative error is less than ± 0.125%, which is suitable for measuring scales of all

materials Heavy, such as building materials, metallurgy, chemical industry, feed and other industries; enterprises' internal and external

settlement, or other occasions with high requirements for symmetry weight precision, are suitable for industries with high requirements for on

-site process or trade settlement. The functions include output monitoring, report generation, real-time video monitoring, automatic alarm and

so on.

Structure features:

1. Fully suspended structure;

2. No trunnion fulcrum and moving parts;

3. It is equipped with four pull sensors, which are directly suspended on the beam;

4. The weight of the material directly acts on the sensor;

5. The measurement of belt weigher is basically zero affected by its own structure;

6. Easy to install, only need eight bolts to install and fix;

[product composition]: weighing frame, imported weighing sensor, speed sensor, weighing instrument, calibration device and software

of "remote monitoring system for production".

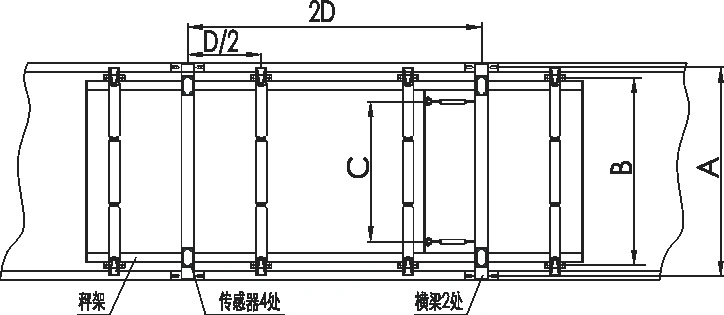

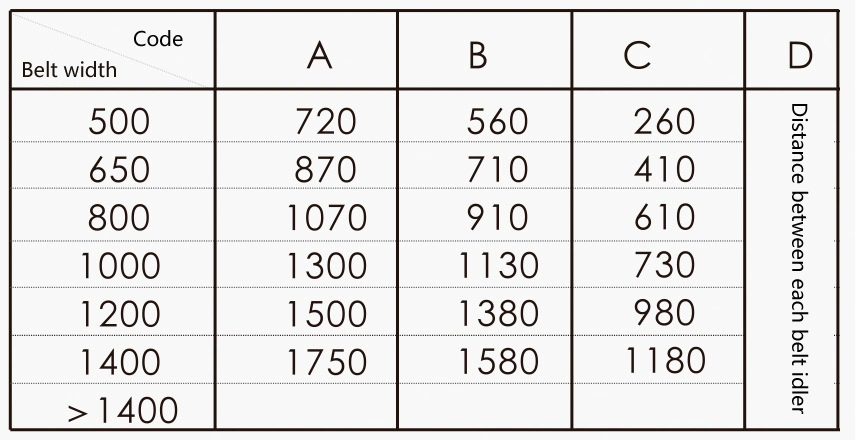

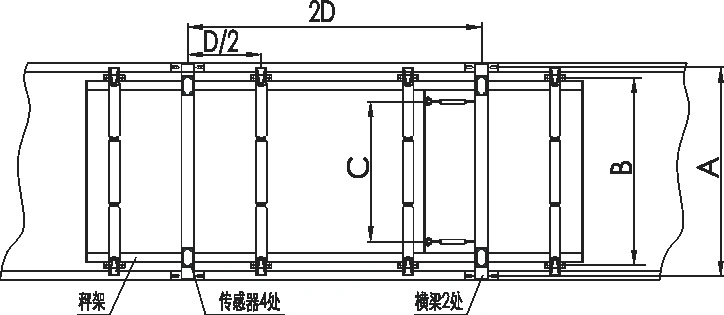

Weighing bridge

Ics-14 weighing bridge consists of four groups of weighing idlers, full floating structure, no trunnion fulcrum and moving parts. Rectangular

steel pipe design is adopted, the whole weighing bridge has enough high rigidity and small self weight, and the surface ash area reaches the

lowest. The high-precision strain gauge sensor is installed in the tension position to reduce the nonlinear error and ensure the stability of the

whole system with minimal maintenance. Four pull type load cells are suspended on two beams to provide support for the symmetrical load

bridge. The load bridge is a unit component structure, which can be easily and quickly installed on site. Only eight bolts are needed for

installation and fixation.

The weighing sensor

Ics-14 series electronic belt weigher adopts pull type electronic strain gauge load cell. The main technical indexes are as follows:

Enclosure: "s" seal protection

Nonlinear: < 0.03% FS

Non repeatability: < 0.01% FS

Creep: < 0.02% FS

Zero point output: ± 1%

Under the maximum flow rate, the displacement of the force application point of the sensor elastomer is not more than 0.2mm

Temperature sensitivity: interval: 0.0008% FS / of

Zero: 0.0015% FS / of

Lag error: 0.02%

Sensitivity error: ± 0.1%

Overload capacity: 150% of sensor capacity

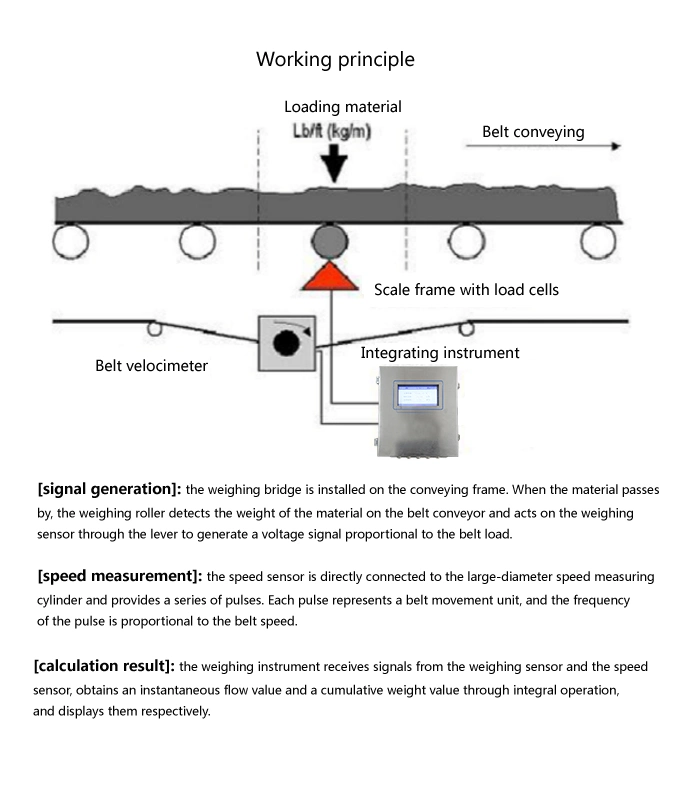

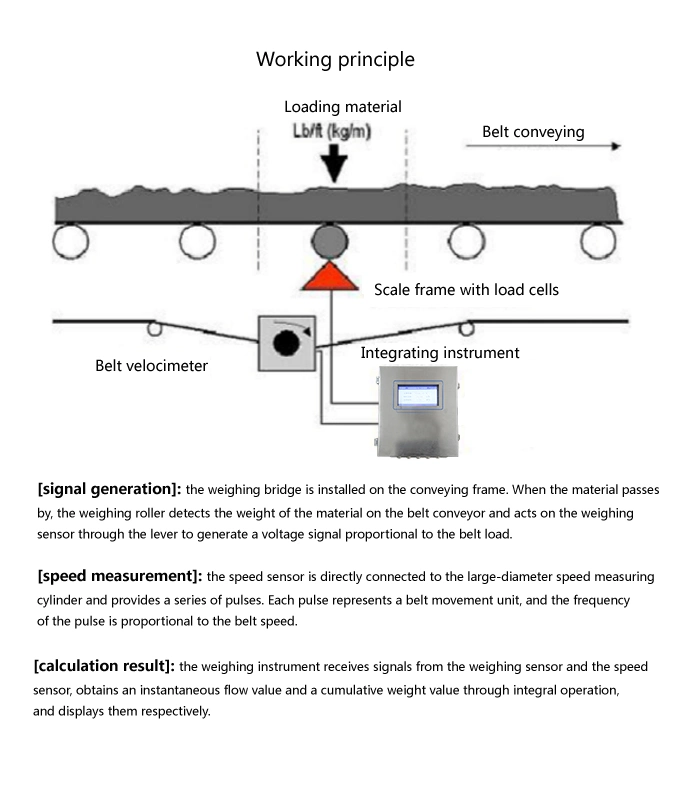

Speed sensors 60-12c, 60-12b

The speed sensor is installed on the tail roller, large diameter roller or speed measuring roller, and the speed measuring roller / roller is

installed on the upper surface of the return belt to eliminate the impact of belt slipping. The speed sensor is a digital brushless pulse generator.

When the belt is running, the speed sensor sends out a series of speed pulses. Each pulse represents a unit length of belt travel, and the

pulse frequency is proportional to the belt speed.

The shell material is cast aluminum, which can adapt to the open air working environment

The AC pulse generator does not need to adjust or replace the carbon brush

Brushless AC pulse generator, no adjustment, calibration, maintenance free

The latest soft connection technology, more effectively ensure the speed accuracy, and greatly improve the service life of the equipment

TK1000 weighing control instrument

Adopt 32-bit CPU and 24 bit a / D to speed up the operation speed and improve the metering accuracy;

All data of the belt scale are displayed on the high brightness four line vacuum fluorescent screen;

Menu panel operation mode, in line with people's computer operation habits;

When the relevant data of the belt scale is changed, the original data can be retained for inquiry to reduce human errors;

Provide multi-level password protection to facilitate different users; provide linear compensation to make the belt scale have the same

accuracy when the rated load is 25% to 100%;

Optional analog output for displaying material flow, weight or speed;

Analog output delay can be selected for actual control;

The analog input and output board (one or two voltage and current input and output) can be selected for control or compensation;

The RS-232 / RS-485 communication board can be selected, and one of the two modes can be selected from the hardware setting;

Models 2001 and 2105 of 2000 series instruments are available for users;

Lk1000 weighing instrument

The display is a double screen digital display, the upper screen shows the cumulative flow, and the lower screen shows the instantaneous flow;

The digital input and output are called out in the form of command code by pressing the key. For example, 01p represents the zero value;

Remote counting can be done in two ways: contact and non-contact. When there is no contact, the output is DC 24 V signal;

The optional communication board is used for upper computer communication, and the communication mode is RS-485 standard port;

Current output board can be selected to output standard 0-20mA or 4-20mA signal;

The output interface can be connected to MP or PP series parallel port printer.

Technical specification:

Please advise your technical specification about existing belt conveyor and provide your technical

requirements about belt scale and installation dimension for us,we will supply different types of

customized belt scale to you.

Reference:

OUR WORKSHOP

Our Services

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

Sale of services:

1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. Where to buy our products for 1 years warranty and life long maintenance.

2. 24-hours telephone service.

3. A large stock of components and parts, easily-worn parts.

FAQ

Q:Why choose us ?

A: New power of embroidery manufacturer with most advanced and stable technology, our own patent and invention,

Golden supplier ,low price ,excellent quality , Prompt Delivery time ,reputation first ,customer first!

Q:How about the warranty?

A: All of our products have 12 months warranty.also will send a part of the accessories along with goods.

Q:What package dose your factory use?

A:International standard carton packaging or flight case as your requirement, using the EPE for safeguard,

they will protect the product not damage.

Q:What paymet methods do you accept?

A:T/T,L/C, CASH, WESTERN UNION, Money Gram,

Q:When you will ship the product after i send the money?

A:Its depend on order quantity, small order will take 3-5 work days, large order will take 5-15days ,if the item

in store, we will ship 3days after the payment.

Q:If have some problems, do you have any After Service?

A:Of course! Firstly, you need send the picture or video to us, let us make sure what's problem about the

product, if this problem can use parts to solve, we will send the replacements for free, if the problem can't solve,

We will replace it by courier or in your next order for compensation.

Packaging & Shipping

Standard Export Packing:

International standard carton packaging or flight case as your requirement, using the EPE for safeguard, they will

protect the product not damage.

Thanks for choosing X-ING as your reliable partner and please

trust both of us will create a brilliant future!

Belt weigher is an automatic weigher that continuously weighs bulk materials on the conveyor belt without subdividing the mass or

interrupting the movement of the conveyor belt.

ics-14 high precision electronic belt weigher adopts full suspension weighing bridge. This kind of bridge has no fulcrum and movable parts.

The long-term stability and high precision of this kind of electronic belt weigher are incomparable with other electronic belt weighers. Digital

signal transmission and processing technology, dynamic cumulative error is less than ± 0.125%, which is suitable for measuring scales of all

materials Heavy, such as building materials, metallurgy, chemical industry, feed and other industries; enterprises' internal and external

settlement, or other occasions with high requirements for symmetry weight precision, are suitable for industries with high requirements for on

-site process or trade settlement. The functions include output monitoring, report generation, real-time video monitoring, automatic alarm and

so on.

Structure features:

1. Fully suspended structure;

2. No trunnion fulcrum and moving parts;

3. It is equipped with four pull sensors, which are directly suspended on the beam;

4. The weight of the material directly acts on the sensor;

5. The measurement of belt weigher is basically zero affected by its own structure;

6. Easy to install, only need eight bolts to install and fix;

[product composition]: weighing frame, imported weighing sensor, speed sensor, weighing instrument, calibration device and software

of "remote monitoring system for production".

Weighing bridge

Ics-14 weighing bridge consists of four groups of weighing idlers, full floating structure, no trunnion fulcrum and moving parts. Rectangular

steel pipe design is adopted, the whole weighing bridge has enough high rigidity and small self weight, and the surface ash area reaches the

lowest. The high-precision strain gauge sensor is installed in the tension position to reduce the nonlinear error and ensure the stability of the

whole system with minimal maintenance. Four pull type load cells are suspended on two beams to provide support for the symmetrical load

bridge. The load bridge is a unit component structure, which can be easily and quickly installed on site. Only eight bolts are needed for

installation and fixation.

The weighing sensor

Ics-14 series electronic belt weigher adopts pull type electronic strain gauge load cell. The main technical indexes are as follows:

Enclosure: "s" seal protection

Nonlinear: < 0.03% FS

Non repeatability: < 0.01% FS

Creep: < 0.02% FS

Zero point output: ± 1%

Under the maximum flow rate, the displacement of the force application point of the sensor elastomer is not more than 0.2mm

Temperature sensitivity: interval: 0.0008% FS / of

Zero: 0.0015% FS / of

Lag error: 0.02%

Sensitivity error: ± 0.1%

Overload capacity: 150% of sensor capacity

Speed sensors 60-12c, 60-12b

The speed sensor is installed on the tail roller, large diameter roller or speed measuring roller, and the speed measuring roller / roller is

installed on the upper surface of the return belt to eliminate the impact of belt slipping. The speed sensor is a digital brushless pulse generator.

When the belt is running, the speed sensor sends out a series of speed pulses. Each pulse represents a unit length of belt travel, and the

pulse frequency is proportional to the belt speed.

The shell material is cast aluminum, which can adapt to the open air working environment

The AC pulse generator does not need to adjust or replace the carbon brush

Brushless AC pulse generator, no adjustment, calibration, maintenance free

The latest soft connection technology, more effectively ensure the speed accuracy, and greatly improve the service life of the equipment

TK1000 weighing control instrument

Adopt 32-bit CPU and 24 bit a / D to speed up the operation speed and improve the metering accuracy;

All data of the belt scale are displayed on the high brightness four line vacuum fluorescent screen;

Menu panel operation mode, in line with people's computer operation habits;

When the relevant data of the belt scale is changed, the original data can be retained for inquiry to reduce human errors;

Provide multi-level password protection to facilitate different users; provide linear compensation to make the belt scale have the same

accuracy when the rated load is 25% to 100%;

Optional analog output for displaying material flow, weight or speed;

Analog output delay can be selected for actual control;

The analog input and output board (one or two voltage and current input and output) can be selected for control or compensation;

The RS-232 / RS-485 communication board can be selected, and one of the two modes can be selected from the hardware setting;

Models 2001 and 2105 of 2000 series instruments are available for users;

Lk1000 weighing instrument

The display is a double screen digital display, the upper screen shows the cumulative flow, and the lower screen shows the instantaneous flow;

The digital input and output are called out in the form of command code by pressing the key. For example, 01p represents the zero value;

Remote counting can be done in two ways: contact and non-contact. When there is no contact, the output is DC 24 V signal;

The optional communication board is used for upper computer communication, and the communication mode is RS-485 standard port;

Current output board can be selected to output standard 0-20mA or 4-20mA signal;

The output interface can be connected to MP or PP series parallel port printer.

Technical specification:

| Model# | Calibration accuracy % | Weighing range(t/h) | Inclination of belt conveyor | Load cells(piece) | Metering idler(unit) | Pressure lever | Trunnion (piece) | Speed sensor (piece) |

| ICS-14A | ±0.125 | 1-8000 | ≤6° | 4 | 4 | Suspension | None | 1 |

| ICS-14B | ±0.125 | 1-8000 | ≤17° | 4 | 3 | Suspension | None | 1 |

| ICS-17A | ±0.25 | 1-6000 | ≤17° | 2 | 4 | Double lever | 4 | 1 |

| ICS-17B | ±0.25 | 1-4000 | ≤17° | 2 | 2 | Single lever | 2 | 1 |

| ICS-20A | ±0.5 | 1-8000 | ≤17° | 1 | 2 | Double lever | 2 | 1 |

| ICS-20B | ±0.5 | 1-8000 | ≤17° | 1 | 1 | Single lever | 2 | 1 |

| ICS-30A | ±0.25 | 1-8000 | ≤17° | 2 | 1 | Suspension | None | 1 |

| ICS-30B | ±0.25 | 1-8000 | ≤17° | 1 | 1 | Suspension | None | 1 |

| ICS-30-2TC-4C | ±0.125 | 1-8000 | ≤17° | 4 | 2 | Suspension | None | 1 |

| SN-XF-4 | ±0.125 | 1-8000 | ≤6° | 8 | 8 | Suspension | None | 1 |

Please advise your technical specification about existing belt conveyor and provide your technical

requirements about belt scale and installation dimension for us,we will supply different types of

customized belt scale to you.

Reference:

OUR WORKSHOP

Our Services

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

Sale of services:

1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. Where to buy our products for 1 years warranty and life long maintenance.

2. 24-hours telephone service.

3. A large stock of components and parts, easily-worn parts.

FAQ

Q:Why choose us ?

A: New power of embroidery manufacturer with most advanced and stable technology, our own patent and invention,

Golden supplier ,low price ,excellent quality , Prompt Delivery time ,reputation first ,customer first!

Q:How about the warranty?

A: All of our products have 12 months warranty.also will send a part of the accessories along with goods.

Q:What package dose your factory use?

A:International standard carton packaging or flight case as your requirement, using the EPE for safeguard,

they will protect the product not damage.

Q:What paymet methods do you accept?

A:T/T,L/C, CASH, WESTERN UNION, Money Gram,

Q:When you will ship the product after i send the money?

A:Its depend on order quantity, small order will take 3-5 work days, large order will take 5-15days ,if the item

in store, we will ship 3days after the payment.

Q:If have some problems, do you have any After Service?

A:Of course! Firstly, you need send the picture or video to us, let us make sure what's problem about the

product, if this problem can use parts to solve, we will send the replacements for free, if the problem can't solve,

We will replace it by courier or in your next order for compensation.

Packaging & Shipping

Standard Export Packing:

International standard carton packaging or flight case as your requirement, using the EPE for safeguard, they will

protect the product not damage.

Thanks for choosing X-ING as your reliable partner and please

trust both of us will create a brilliant future!